Free-Flex® Pivots and traditional ball bearings both set out to accomplish the same goal: providing rotational motion in a mechanical design. However, each product has certain advantages and disadvantages that must be taken into account before deciding which mechanism would be right for your design.

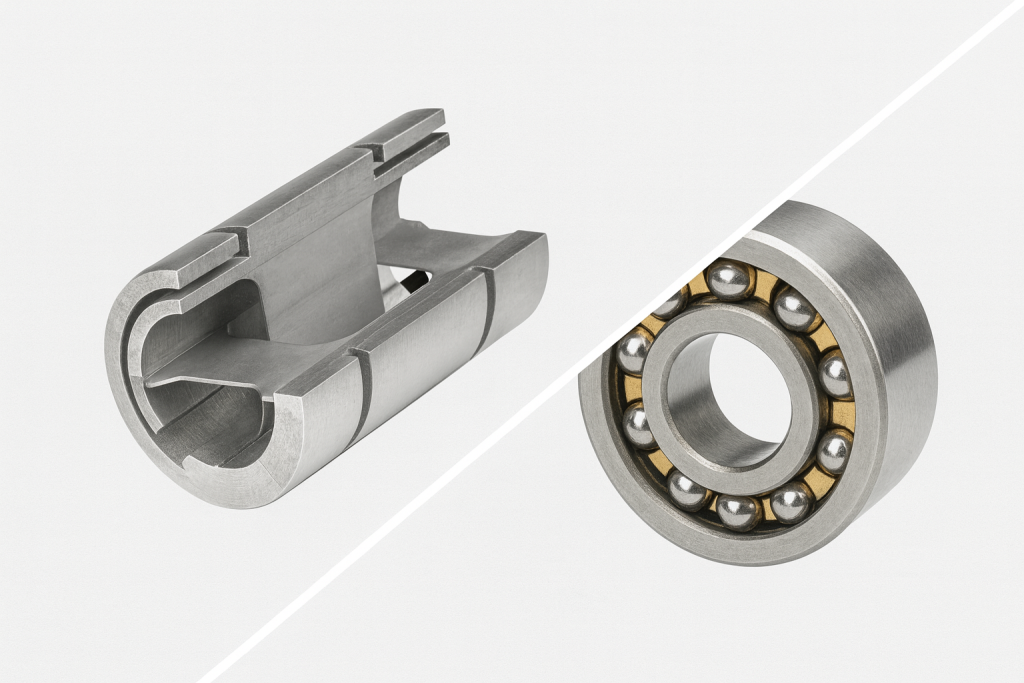

It is first important to know how these two mechanisms work. Firstly, the Free-Flex® Pivot bearing, which derives its motion from an applied torque to the outer sleeve of the part. When one end of a cantilever part is fixed, the applied torque on the free end of the part causes the crossed leaf springs in the center of the part to flex, allowing for the part to rotate. When the torque is released, the restoring torsional spring rate of the pivot will then cause the part to snap back into its neutral position. When pivots rotate there is no friction as there is no contact between the rotating parts, which eliminates the need for lubrication. There is also no backlash.

Ball bearings on the other hand separate moving parts with rolling elements between raceways. When properly lubricated and sealed ball bearings can provide continuous, low friction rotation. Lubrication is essential to overall bearing health, as it also aids in resisting corrosion and keeping contamination out.

Now, how do these two parts stack up in terms of key performance areas?

| Feature | Ball Bearings | Free-Flex® Pivot Bearings |

|---|---|---|

| Range of Motion | Unlimited rotation with many different bearing types for misalignment (such as self-aligning). | Limited angular travel by design; excellent for use when motion stays within the elastic range of the part. |

| Friction and Stiction | Low friction when lubricated, but have start-up torque and can exhibit stick-slip at small motions depending on preload and lubricant. | No rolling or sliding contacts, resulting in no friction or backlash, allowing highly repeatable micromotion. |

| Precision and Backlash | Backlash can be driven to near zero depending on clearances and preload, but never fully eliminated. Torque ripple can cause issues in certain precision applications (e.g., metrology). | Backlash-free with highly uniform torque. |

| Load Capacity and Stiffness | Very high radial/axial load capacities for their size; well-documented lifespans. | Load capacities depend on pivot outer diameter and spring thickness. Excellent stiffness within the elastic range but not a substitute for high-load, high-rotation applications. |

| Environment | Greases and oils can outgas in vacuum. Dry-film lubricants raise torque scatter, especially at cryogenic temperatures. | No grease or oil to outgas, making them ideal for vacuum and cleanroom environments. |

The Verdict

Each contender has specific use cases where they outshine the other. When it comes to unlimited rotation and high load applications, the ball bearing is the clear victor. In applications where frictionless, stiction free, repeatable motion is required in extreme environments the Free-Flex® Pivot bearing stands head and shoulders above the competition.

Still not sure if the Free-Flex® Pivot is right for your application? Have some additional questions on performance characteristics? Contact the Free-Flex® Pivot engineering team for assistance today!